Smoking chambers

Our offer

- smoking chambers for fish industry

- smoking chambers for meat industry

- we have also smokehouses for gastronomy and hobbyists who need proffesional solutions: smoking chambers

Smoking-chambers produced by our company enable the performance of all the heat processing operations of cured meat products, poultry, fish and cheese, such as drying, roasting, cooking, hot-air smoking, cold-air smoking and steaming.

The steaming-chamber unit consist of:

- a heat-chamber

- a smoke-generator

- an air-preparation unit

- a steering-cabinet equipped with a microprocessing controlle

Smoking-chambers can take from 1 to 2,3,4,6,8,10 or 12 standard smoking-trolleys measuring 1000x1000x2000 mm.

The construction of the chamber together with the casing is made of stainless steel.

The supporting construction is assembled from specially made sections joining the front and back wall.In the front wall is installed a door equipped with a silicon seal ensuring the leaktightness of the chamber.

Inside the chamber two ventilation channels are installed equipped with condensation release pipes.

The ceiling and the walls of the chamber have a perfect heat isolation made from hard mineral wool gr. 50 mm.

If the customer so wishes the chamber may be equipped with a washing-unit as well as a smoke-purification-filter.The consecutive stages of the operation of the chamber are independently controlled by the microprocessor.

Smoke - generator

The smoke-generator serves to produce smoke in amounts sufficient for continuity of the smoking process. The smoke-generator consist of stainless-steel frame, in which are installed:

- a furnace-sleeve with an ignition-heater

- a grate

- a rotary chip-feeder

- an ash-pit

- a condensation-container

- a water and compressed air instalation

The smoke-generator burns 3-10 mm smoking chips.It has a container for chips with a capacity of 50 l. It is equipped with an electric ignition system. The mixer continually feeds chips into the burning-chamber. The grate has a rotary-comb which cleans the surface of the grate during operation. The smoke outlet is equipped with a system for sprinkling, and puryifying smoke.

The built-in temperature-sensor controls the temperature of combustion, and in case of the chips catching fire, it automatically activates the extinguishing system. The operation of the smoke-generator is controlled by the microprocessor.

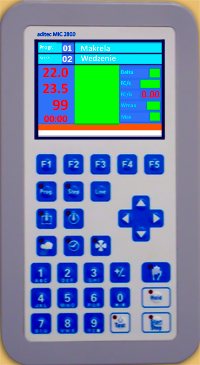

Microprocessor MIC-2500

The microprocessing controller operates and controles the course of the technological process in the chamber; it operates the functioning of flaps, the smoke-generator ignition and then selects operating levels of the smoke-generator. It has an option of programming 99 operating programs, with 20 steps each. The 12-touch keyboard is not encoded, which allows programming different variants in the program. It is possible to program :

- the temperature inside the product

- the temperature inside the chamber

- the temperature growth in time

- the relative hunidity

- the time of operation

- the time before the termination of the process

- the program-number

- the step-number

The specific parameters can be corrested without changing the main program or interrupting the operation of the chamber.

At each moment of the operation there is a possibility of displaying the assigned parameters and comparing them with the currently existing ones.The microprocessor is installed in the steering-cabinet made of steel sheet, coated in chemically hardened enamel(leakproof) with a protection level IP-56. The steering-cabinet can be installed on the wall or on a special stand.

Smoking-chambers parameters:

|

Type of Smoking-chamber: heating: - electric heating, - gas, oil, - steam |

Dimensions (mm) L / B / H |

Loading (kg) | Power (kW) | ||

| KWG-800 | 1030 | 1250 | 2035 | 100 | 18,0 |

|

KWG-1 KWZ-1 KWGZ-1 KWP-1 |

1290 | 1450 | 2565 | 200 ÷ 250 |

25,0 7,0 25,0 51,0 |

|

KWG-2 KWZ-2 KWGZ-2 |

3290" 3590 |

1700 | 2360 | 400 ÷ 500 |

49,0 13,0 49,0 |

|

KWG-3 KWZ-3 KWGZ-3 |

4490" 4790 |

1700 | 2360 | 600 ÷ 750 |

73,0 19,0 73,0 |

|

KWG-4 KWZ-4 KWGZ-4 |

5690" 5990 |

1700 | 2360 | 800 ÷ 1000 |

97,0 25,0 97,0 |

" - only for the realisation E

Symbol of smoking-chamber type:

KW -- ... -- ... ------------------------ ... -- ... -------------------------- ... -- ...

| Destination of type of smoking chamber: | Type of heating: | Type of steering cabinet: |

|

for hot-air-smoking: G for cold-air-smoking: Z for hot-and-cold-air-smoking: GZ for roasting: P |

Electric: E Gas: G Oil: O Steam: P Mixed: EP |

S1 - with MIC 2500 S2 - without a controller |

| Capacity: | Type of smoke generator: | Realisation: |

| number of trolleys: 1,2,3,4,6,8,10,12 |

D1 - run on chips D2 - run on wood waste |

Left: L Right: P Row alignment of trolleys: LP, LL, PP |

exemplary : KWZ-4-E-D1-S1-LP